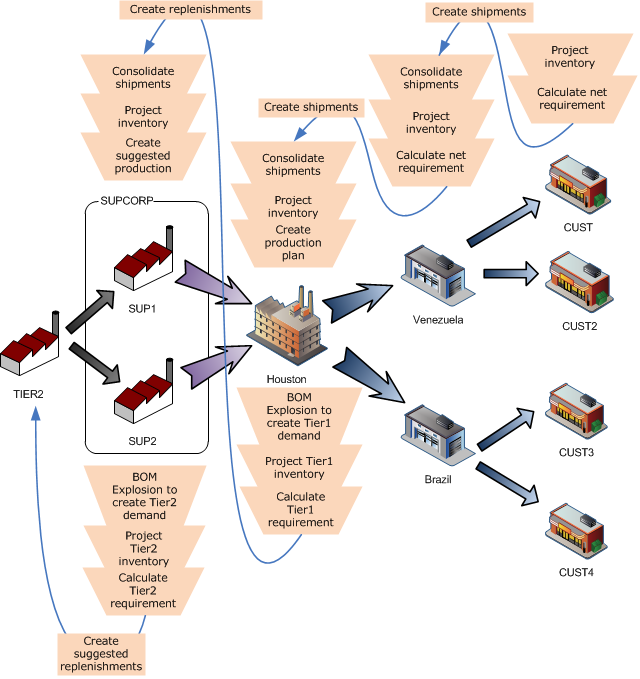

Use Case: How VCRP™ Planning & Response Works

- VCRP™ using the CAF Platform technology, enables Multi-tier visibility of plans, actual demand, inventory, supply capacity and logistics lead times, from End Customer, Distributor, OEM planner and Supplier view points. Data is synchronized daily using an in built master data management tool and is exchanged with all partner sites in their own format and nomenclature

- VCRP™ performs Auto Planning and Auto Execution to accommodate unexpected impacts across multiple tiers, if possible, within pre-established/configurable business policy rules. Where no solution exists that respects both requirements and supply policies, manual intervention is alarmed and escalated

- Planners manually step through highlighted, unsolved issues and prioritize best choices, using scenario planning tools and collaborative multi-partner interaction in real time, inside the platform

- VCRP™ feeds resulting decisions to all partner systems of record for execution

- Automatic closed-loop follow up occurs, as well as KPI monitoring on a continuous basis

The result is that the customer is satisfied, other customers’ needs are respected, and the response is executed efficiently. No panic. No Firefighting.

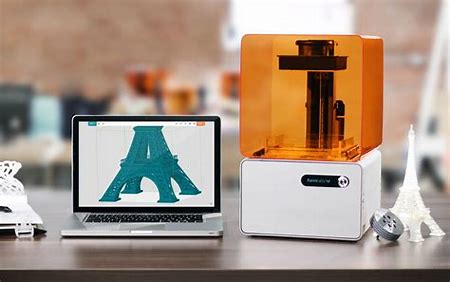

Formlabs Leverages Vecco to Manage Global Demand, Supply, and Inventory Operations

Leading 3D printer manufacturing company deploys next generation supply chain management system to orchestrate supply and demand across their rapidly expanding global supply chain. MALVERN, PA. Vecco International, provider of an advanced end-to-end cloud-based...

Have A Question

VCRP™ Has Proven Implementations To Over 3,000 Trading Partners

Recent News

Formlabs Leverages Vecco to Manage Global Demand, Supply, and Inventory Operations

Leading 3D printer manufacturing company deploys next generation supply chain management system to orchestrate supply and demand across their rapidly expanding global supply chain. MALVERN, PA. Vecco International, provider of an advanced end-to-end cloud-based...

Is Lack of Real-Time Synchronized Data Threatening Your Ability to Service Your Customers?

Your Business has just received great news: your sales for a specialty item manufactured in-house are through the roof. In fact, they’re way over forecast. However, as the Supply Chain Planner, there’s bad news: you’re short on...

Supply Chain 4.0 enabling the ‘Digital Enterprise’ and Industry 4.0

The real value of the "Digital Enterprise" movement & Industry 4.0 can only be realized unless it is encompassed and orchestrated by parallel automation / Digitization of the 'Supply Chain' delivery mechanism. "Global supply chain flows must become increasingly...